Battery Thermal Management: Avoid Overheating Issues

Ever wondered why your electric vehicle’s battery performance changes with temperature? The answer is battery thermal management. It’s a key tech that keeps your battery working well and safely.

The battery pack thermal management system is more than just tech. It’s the protector of your car’s heart. Modern batteries need careful temperature control to work their best and last longer.

Think of your battery as a living thing. Like us, it does its best in a certain temperature range. If it gets too cold or too hot, it doesn’t work well, and it might even get damaged.

Electric vehicle batteries do their best between 20°C and 40°C. This is the perfect spot for power, efficiency, and safety. But, if the temperature gets too far from this range, it can hurt your battery’s health. It can make it less efficient, reduce power, and age faster.

Table of Contents

Understanding Battery Thermal Management

Battery thermal management is key to keeping energy storage systems running well and safely. It’s all about keeping the battery at the right temperature. This is why it’s so important in today’s battery designs.

This technology uses smart ways to control the battery’s temperature. The main aim is to keep the battery between 20-30°C (68-86°F). This is where it works best.

What is Battery Thermal Management?

Battery thermal management is about keeping the battery cool during use. It uses:

- Temperature sensors

- Cooling mechanisms

- Heat distribution systems

- Monitoring electronics

Importance of Thermal Regulation

Good battery thermal modeling is vital to avoid risks. If the temperature gets out of control, it can cause big problems:

| Temperature Impact | Potential Consequences |

|---|---|

| High Temperatures | Battery degradation, increased thermal runaway risk |

| Low Temperatures | Reduced chemical reaction rates, decreased performance |

“Temperature control is not just about performance—it’s about safety and longevity.” – Battery Engineering Experts

New cooling methods for lithium-ion batteries have improved a lot. These systems can keep the battery at a stable temperature, no matter what. Your battery’s safety and performance depend on these new thermal management techniques.

The Science Behind Battery Temperature

Battery performance is tied to temperature. Knowing how heat impacts your battery can extend its life and avoid safety hazards.

How Temperature Impacts Battery Performance

Batteries work best in a certain temperature range. Optimal performance occurs between 20 and 30°C (68 and 86°F). Temperatures outside this range cause several issues:

- High temperatures speed up chemical reactions

- Low temperatures slow down power generation

- Extreme conditions can cause permanent damage

“Temperature is not just a factor in battery performance—it’s a critical determinant of battery health and longevity.”

Thermal Runaway: Understanding the Risk

Managing heat is key to preventing thermal runaway. This dangerous situation happens when a battery’s temperature gets out of control, leading to failures.

Several factors can lead to thermal runaway:

- Internal short circuits

- Mechanical damage

- Overcharging

- External heat sources

Batteries can heat up fast, reaching about 60°C per minute. The energy used for this heating is small, but the maximum temperature can hit over 800°C.

To prevent thermal runaway, it’s important to understand these temperature-related issues. We need strong management strategies to keep batteries safe.

Common Causes of Overheating

Battery thermal abuse testing shows many important factors that lead to overheating. Knowing these can help keep your battery working well for longer.

Batteries get hot from inside and outside sources. Finding out where heat comes from is key to avoiding problems.

External Heat Sources

Things outside the battery also affect its temperature. Main external heat sources include:

- Direct sunlight exposure

- High ambient temperatures

- Proximity to heat-generating equipment

- Extreme weather conditions

High outside temperatures can make the battery hotter. Studies show that temperatures over 35° C can harm battery performance.

Internal Factors Influencing Heat

Heat inside the battery comes from several main sources:

- Charging and discharging rates

- Internal battery resistance

- Electrochemical reactions

- Battery age and degradation

Testing helps makers see how these inside factors cause heat. Fast charging, heavy use, and chemical wear can make the battery hotter.

A faulty Battery Management System (BMS) can stop temperature checks, leading to overheating dangers.

Knowing these causes lets you manage your battery’s temperature. This can prevent performance problems or safety risks.

Strategies for Effective Thermal Management

Battery thermal management is key for top performance and safety. The right strategy boosts battery life, efficiency, and reliability. This is true for many uses.

Electric cars and high-tech gadgets need smart battery management. This keeps them running at their best. Knowing these strategies helps protect your battery and boosts performance.

Design and Engineering Solutions

Good battery thermal management starts with smart design. Engineers use several important strategies:

- Optimizing cell arrangement to avoid heat buildup

- Using materials that help cool down

- Creating paths for air to flow

- Building small cooling systems

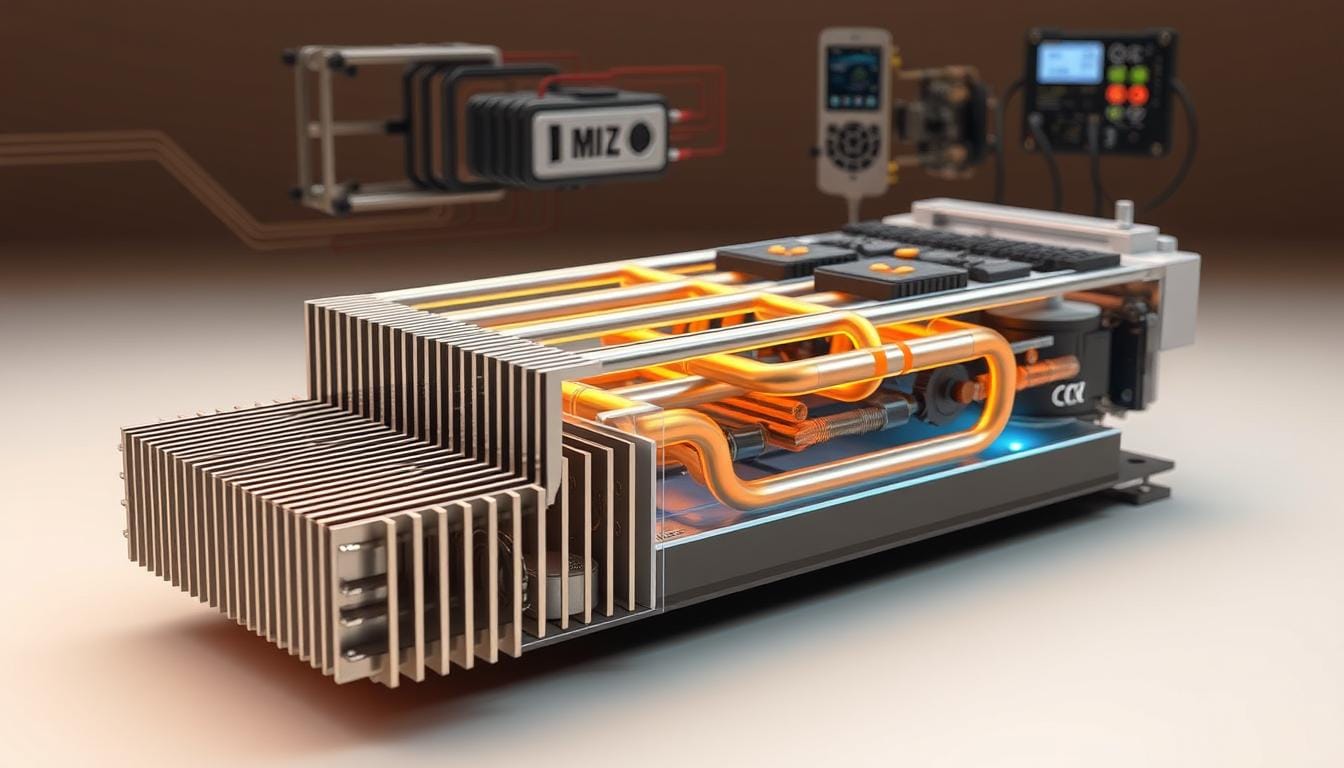

Active Cooling Systems

Active cooling is a top-notch way to manage battery heat. These systems control temperature with precision:

| Cooling Method | Temperature Range | Efficiency |

|---|---|---|

| Air Cooling | 5° – 40° C | Medium |

| Liquid Cooling | 0° – 45° C | High |

| Immersion Cooling | -10° – 50° C | Very High |

Each cooling method has its own benefits. Liquid cooling systems are great at transferring heat, but air cooling is cheaper for smaller setups.

Using smart battery thermal management strategies keeps your tech safe from heat damage. It ensures reliable performance in many settings.

The Role of Materials in Thermal Management

Battery thermal interface materials are key to managing heat. They help keep the battery at the right temperature. This is important for its efficiency, how long it lasts, and safety.

Choosing the right materials for thermal management is very important. Different materials have different effects on heat dissipation and battery performance. Let’s look at the main points:

Heat Conductive Materials

When picking battery thermal interface materials, consider these key points:

- Temperature range tolerance (usually between 15°C and 35°C)

- Thermal conductivity (varies from 0.4 W/m·K to 3 W/m·K)

- Chemical stability and resistance to oxidation

Insulation Techniques

Good thermal management needs both heat conduction and insulation. Silicone-based materials are a top pick because of their great properties:

- Wide temperature tolerance (–80°C to 250°C)

- High fire resistance

- Low toxic emissions

- Available in foam, gel, and adhesive forms

Your battery’s performance depends on keeping it at the right temperature. Advanced battery thermal interface materials prevent overheating, reduce wear, and make batteries last longer.

Advanced Technologies in Battery Thermal Management

Battery thermal management is now in a new era of innovation. New technologies are changing how we manage and improve battery performance. Scientists are working on smart solutions to handle temperature issues in energy storage systems.

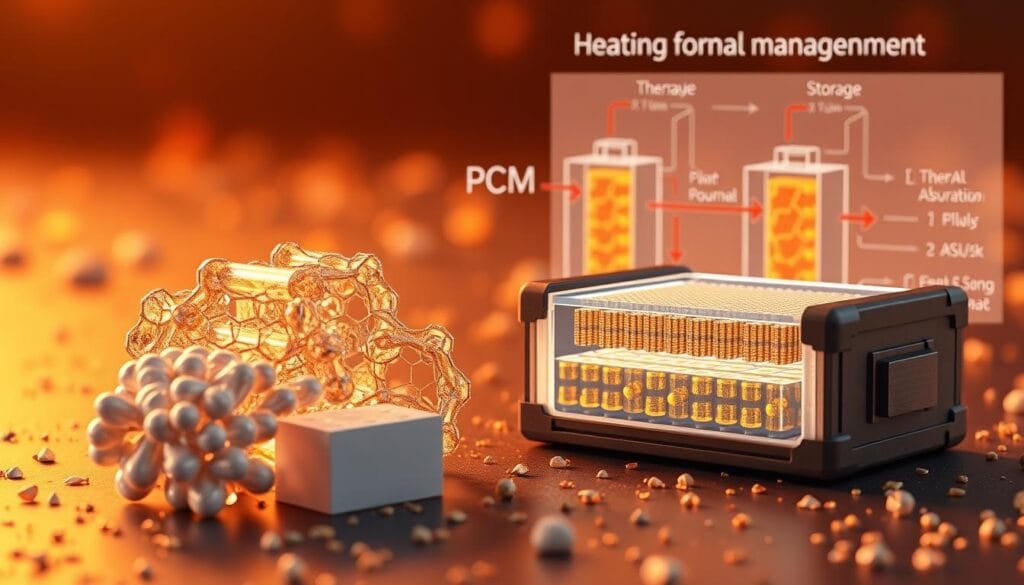

Phase Change Materials: A Revolutionary Approach

Phase change materials (PCMs) are a big step forward in battery thermal management. These materials can take in or give out heat when they change state. This helps keep battery temperatures stable.

- PCMs can stabilize temperatures within 40–55 °C range

- Thermal conductivity reaches up to 1.58 Wm−1K−1

- Latent heat capacity varies between 35.0 and 68.3 Jg-1

Nanotechnology: Transforming Heat Management

Nanotechnology is opening up new ways to better battery thermal performance. Nanostructured materials help in spreading heat more efficiently. This leads to better and quicker thermal management systems.

“Emerging research on nanomaterials promises significant improvements in thermal conductivity and heat dissipation capabilities for future battery technologies.”

By combining phase change materials with nanotechnology, scientists are creating new solutions. These solutions can:

- Reduce temperature swings

- Make batteries last longer

- Boost energy storage efficiency

The future of battery thermal management is bright. These advanced technologies are leading to more dependable and efficient energy storage systems.

Monitoring Battery Temperature

Battery thermal management is key and relies on advanced temperature tracking. Your battery’s performance and safety depend on keeping a close eye on its temperature. This helps avoid risks and boosts efficiency.

Today’s battery systems use smart sensors and monitoring tech for the best thermal conditions. The ideal temperature for Energy Storage System (ESS) battery packs is between 15°C and 35°C. So, keeping an eye on it in real-time is a must.

Tools and Technologies for Temperature Monitoring

There are top-notch tools for tracking temperature:

- Thermocouples for exact temperature checks

- Infrared sensors for detecting heat without touching

- Smart IoT systems for monitoring

- Advanced Battery Management Systems (BMS)

Importance of Continuous Monitoring

Keeping an eye on battery temperature is vital to avoid big problems like:

- Thermal runaway

- Cell damage

- Reduced performance

- Potential safety risks

*Accurate temperature measurement is vital for safe battery operation, especialy during high-intensity charging cycles.*

Systems like the Dukosi Cell Monitoring System offer up to three real-time temperature checks per cell. This boosts thermal management. With advanced sensors and predictive analytics, you can improve your battery’s performance, extend its life, and ensure safety.

Best Practices for Users

Keeping your battery cool is key to its long life and good performance. It’s important to manage heat well in all devices and apps.

Learning to control battery temperature helps avoid damage and keeps your devices working longer. Every device has its own needs, but some tips work for all.

Essential Tips for Maintaining Optimal Battery Temperature

- Avoid exposing devices to direct sunlight or extreme temperatures

- Keep batteries away from heat sources like radiators or car dashboards

- Ensure proper ventilation during charging and usage

- Use original chargers designed for your specific device

- Remove protective cases during extended charging sessions

Recognizing Signs of Battery Overheating

Spotting battery heat problems early can save your device. Look out for these signs:

- Unusual swelling or bulging of the battery

- Excessive heat during charging

- Rapid power drain or unexpected shutdowns

- Discoloration or warping of the device

Today’s smartphones and electric cars have special battery systems. These systems watch the temperature and warn you of problems.

Pro Tip: Regular software updates can improve your device’s thermal management capabilities and overall battery performance.

Following these tips can greatly lower the chance of battery overheating. This helps your devices last longer.

Regulatory Standards and Safety Guidelines

Understanding battery safety is complex. It involves knowing international rules and standards. Testing batteries for heat abuse is key to making energy storage safe in many fields.

Every area has its own rules for battery safety. For example, Japan has the Japanese Industrial Standards (JIS). They give detailed rules for battery safety and performance:

- JIS C8711: Performance criteria for portable lithium secondary batteries

- JIS C8714: Safety testing procedures for lithium-ion batteries

- PSE mark certification mandatory from February 2019

International Regulatory Landscape

The European Battery Regulation (EU2023/1542) sets important rules for makers. By February 2024, they must say how much recycled material is in their batteries:

- Cobalt: 16% recycled content by 2031

- Lithium: 6% recycled content by 2031

- Nickel: 6% recycled content by 2031

Compliance Best Practices

Companies need to do thorough tests on battery heat abuse to follow safety rules. Important tests include:

- External short circuit resistance testing

- Forced discharge assessment

- Cycle life verification

- Mechanical integrity crush tests

Groups like the National Fire Protection Association (NFPA) have set standards. NFPA 855 and NFPA 70 give detailed safety and installation rules for battery systems.

Future Trends in Battery Thermal Management

The world of battery thermal management is changing fast. New discoveries in nanomaterials could make batteries work better. This could change how we handle heat in batteries. The market for electric vehicle battery thermal management systems is expected to grow a lot.

Solid-state batteries are making a big impact. Companies like Robert Bosch and Continental AG are working on better cooling systems. Heat pumps are also showing great promise, improving battery performance in cold weather.

Your next electric car will likely have smarter battery cooling systems. These will use artificial intelligence and new materials. Phase Change Materials (PCM) are being explored for faster cooling. The market for these systems is expected to grow a lot, showing how important they are for green cars.

The push for green technology is driving these changes. Places like Asia Pacific, and China in particular, are leading the way. They are developing new technologies for electric cars and energy storage.